|

|

Post by AZBlues on Dec 29, 2013 23:22:36 GMT -5

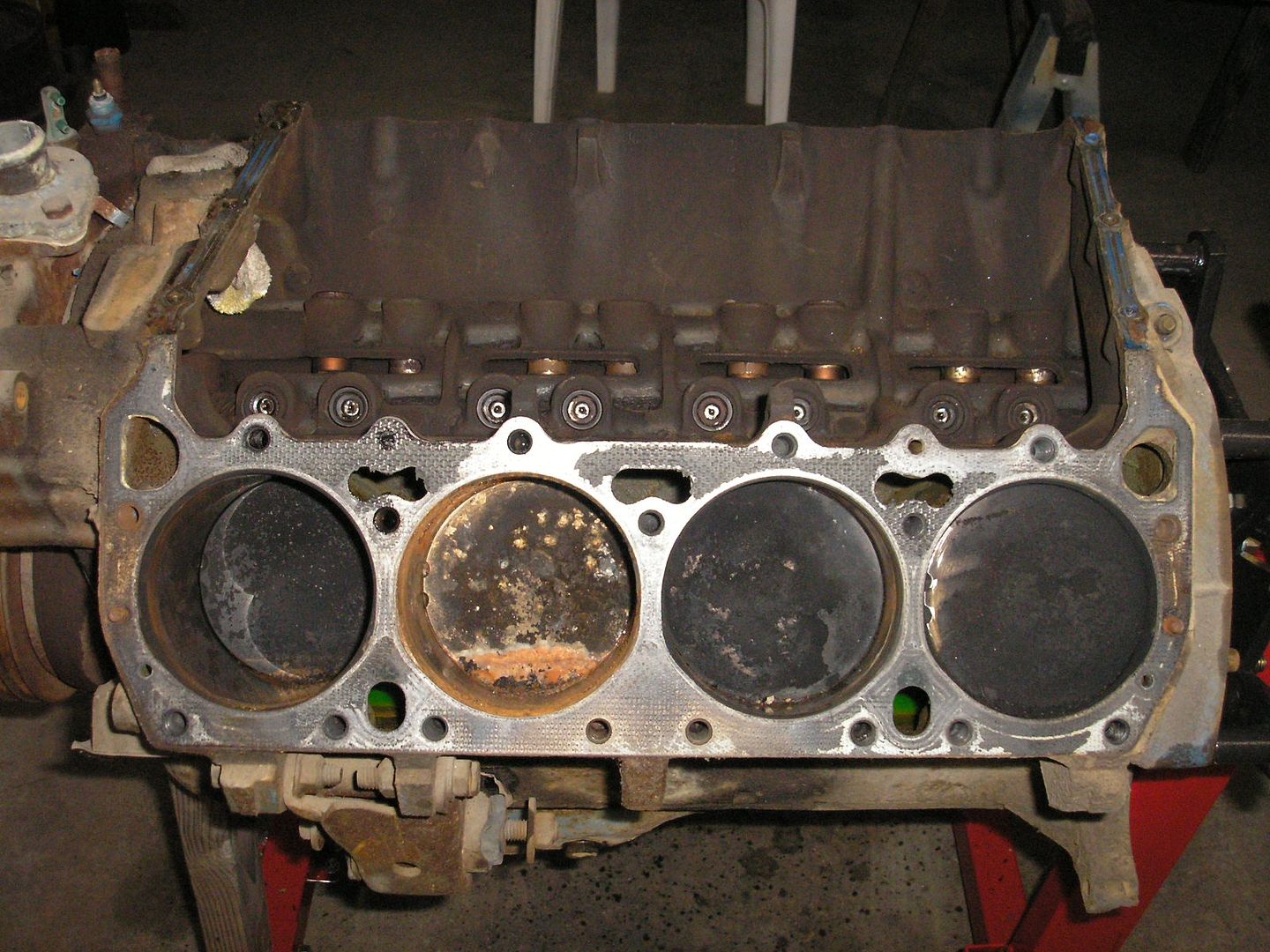

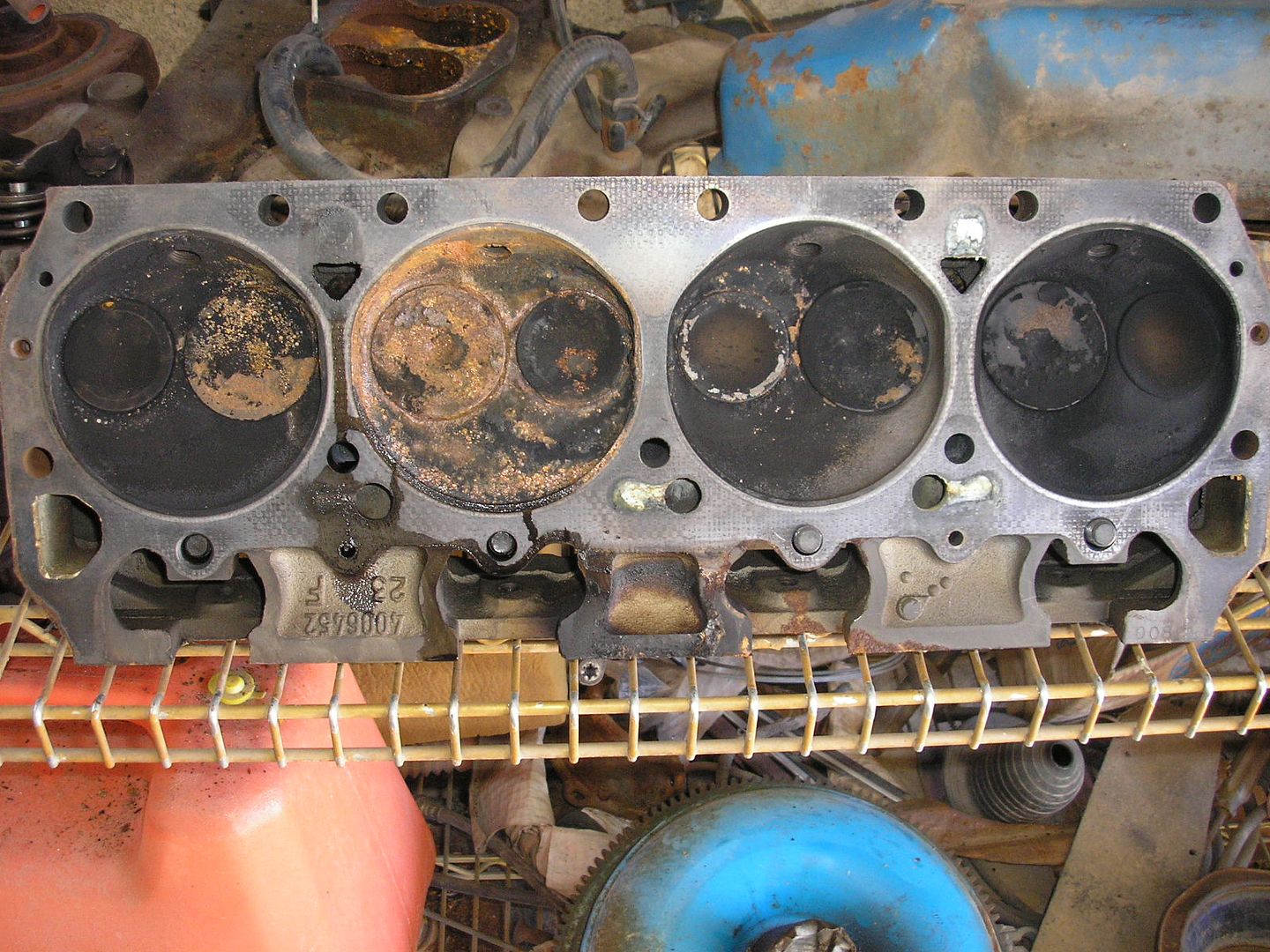

...And it begins, the AZ Bluesmobile build that has had a somewhat slow (7 years) start. Pics will be added infrequently, and sometimes for no reason. The car was bought off of ebay from NY, and is a 98% rust free Georgia car. It's a '75 318 car, back dated to a '74 with correct front bumper, grille, police cluster, and other things that I forgot about.  I couldn't believe that nobody in AZ went for this plate:  The 318 ran good, once I tossed on a new carb, timing chain, and water pump, but it's a good engine for a Dart, not a C-barge. So I had some Mopar friends come over to take the 318/727 out the summer before last...  ( These are Mopar guys) Which left the engine bay ready for the 440, and the car in this state.  Fast forward to now, and with the 440 on a sketchy Harbor Fright engine stand, I pulled the heads off to re-gasket everything, only to find that the schlub that I got the 38K mile engine from left it out in a rain storm...   Funny what people won't tell you. It'll need to be rebuilt, so now I've got to take it to a machine shop to have the short block done, while I figure out what to do with the heads - the big chamber '76 smogger heads probably won't cut it for a 350-375 HP goal. I'm open to suggestions here, as well as the cam, I want smooth power and torque all over the place, with a smooth idle. And that's about it for now. -AZB |

|

|

|

Post by sigmfsk on Dec 30, 2013 4:29:23 GMT -5

I've been looking forward to some updates. A great start! I like this pic:  The spotlight really sets the blumo mood. |

|

|

|

Post by spanks79 on Dec 30, 2013 7:55:50 GMT -5

Great looking car! I'm excited to see more!

That's a bum deal on the engine. But at least you will know what you have when you are done. What is the casting number on the heads you have? Even though they are big chambers they might do pretty good if you can get the compression up a bit. Do your pistons sit below deck at TDC? Mine sit about .079 down. Since you are getting into the bottom end a new set of pistons can bring the pistons to zero and get you a big bump in compression without touching the heads. The "newer" 452 castings flow pretty good according to the research I have done. I toyed around with the idea of aluminum heads, which is the way to go if you need to spend a bunch on money reworking your stockers, but in the end I found a good lightly used set of 452 castings, cleaned them up and milled them to get compression up.

Good luck!

|

|

|

|

Post by AZBlues on Dec 30, 2013 15:28:16 GMT -5

They are 452's.  And with the exception of the light rust, they appear to be virginal. So, flat top pistons at 0 deck, maybe a light shave, and I've got real compression? Aluminum is not in the cards, expensive and kinda out of character for this car. Things are looking up... -AZB |

|

|

|

Post by 58hemifury on Dec 30, 2013 17:49:14 GMT -5

452's are the next best choice to 906 heads for open chamber stock BB Mopar heads, I run them on my '57.

|

|

|

|

Post by Steam McQueen on Dec 30, 2013 23:59:55 GMT -5

...And it begins, the AZ Bluesmobile build that has had a somewhat slow (7 years) start. Heh, well it's about time, lol. I can tell you, honestly, that a couple of times in the last year or so I've looked at your avatar and wondered about your car. This is great stuff, AZB. Cool dog, too! I guess he's got his head turned to bite a flea but he looks like a rock ...  Amazing ... lol, just ribbin' |

|

|

|

Post by AZBlues on Dec 31, 2013 1:06:36 GMT -5

Thanks Steam. That's my guard rock. Max says woof.  -AZB |

|

|

|

Post by Steam McQueen on Dec 31, 2013 2:19:47 GMT -5

Lol. - The eyes on Max ...  ... I think it was at da BBC where I can remember first reading about heterochromia because of Dan having the different eyes. There doesn't seem to be a caninechromia so I guess the Penguin was right all along, we're all animals. Ha not that makes any sense but I remember one of the Nun's we had as a teacher in high-school and I believe she called us animals. - en.wikipedia.org/wiki/Heterochromia_iridum  |

|

|

|

Post by Lord Vadus on Dec 31, 2013 18:36:14 GMT -5

That's unfortunate about the block needing a rebuild, but your car will be better off for it.

I had a similar dilemma with the motor from the '77 New Yorker that I used. It ran like a top and made plenty of power; previous owner was a kid who had lightly hot-rodded Grandpa's old car, but I wanted to be SURE that the motor in my car was one I knew I could trust.

Like you, I'm also not a Mopar guy. I'm a Cadillac man through-and-through; though, I'm also rather partial to Ford.

I decided to enlist the help of a Mopar specialist who knew the difference between an AMC 360 and a Mopar one in detail; the perfect guy to help me build a heavy-duty 440.

Now I have an engine that is all new, running a mild cam, ZERO emissions setup, and a properly-tuned high-flow carb.

It cost me more than I would have liked it to, but it was well worth it; especially when I started horse-trading a few things to finance the build.

It looks like you're going to have a fine car there and a good crew to help. I'm glad to see some progress and can completely relate to the delays.

|

|

|

|

Post by spanks79 on Dec 31, 2013 20:11:32 GMT -5

They are 452's.  And with the exception of the light rust, they appear to be virginal. So, flat top pistons at 0 deck, maybe a light shave, and I've got real compression? Aluminum is not in the cards, expensive and kinda out of character for this car. Things are looking up... -AZB Those look like virgin heads. If they had been milled the casting number itself would be shaved slightly. My 440 came out of a 1975'ish motorhome. With the pistons .079 in the hole and aftermarket fiber head gaskets I calculated compression ratio to be about 7.5 to 1. I did not want to get into the bottom end because it was solid and fresh like yours before the rain storm. I ended up having .030 milled off of my heads PLUS I believe they had already been cut once before, so I guess about .050 has been removed from the heads. My combustion chambers ended up at 75cc's. 452 heads start around 90 cc's. Now I calculate my compression ratio with the milled heads and a stock type .020 steel shim head gasket to be 10 to 1. I was able to get there without touching the bottom end. Since it looks like you are going to have to get into the bottom end any how, if you install different pistons and get them to near zero or even just .020 down you might be able to just clean up your heads and install them without milling them or maybe just a clean up cut on them and still get compression up to the 9.5 - 10 range. I think a lot depends on what you find once the bottom end is apart. If you need new pistons then get the ones you need, if you can re use your pistons you need to figure out what makes more economical sence. New pistons or head work. Most will tell you that new pistons or decking the block is the way to go, not cutting the hell out of the heads like I did. |

|

|

|

Post by countrybunker on Dec 31, 2013 20:47:14 GMT -5

I'm diggin the white paint! Hmm....

|

|

|

|

Post by AZBlues on Dec 31, 2013 21:46:49 GMT -5

That's unfortunate about the block needing a rebuild, but your car will be better off for it. I had a similar dilemma with the motor from the '77 New Yorker that I used. It ran like a top and made plenty of power; previous owner was a kid who had lightly hot-rodded Grandpa's old car, but I wanted to be SURE that the motor in my car was one I knew I could trust. Like you, I'm also not a Mopar guy. I'm a Cadillac man through-and-through; though, I'm also rather partial to Ford. I decided to enlist the help of a Mopar specialist who knew the difference between an AMC 360 and a Mopar one in detail; the perfect guy to help me build a heavy-duty 440. Now I have an engine that is all new, running a mild cam, ZERO emissions setup, and a properly-tuned high-flow carb. It cost me more than I would have liked it to, but it was well worth it; especially when I started horse-trading a few things to finance the build. It looks like you're going to have a fine car there and a good crew to help. I'm glad to see some progress and can completely relate to the delays. It's a real learning curve for me, but I'm a reasonably quick study. This one won't be real cheap, but a wise man once said "Buy quality, cry once." I've learned that lesson. I like this car, I'll keep it for a long time, might road trip it when a Bluesmobile or cop car event comes up, so it has to be trustworthy and right. My engine shop has already been chosen, spoke to the owner, who I've known for nearly 20 years, and I'm taking it there on Thursday. AZB |

|

|

|

Post by AZBlues on Dec 31, 2013 22:02:25 GMT -5

Those look like virgin heads. If they had been milled the casting number itself would be shaved slightly. My 440 came out of a 1975'ish motorhome. With the pistons .079 in the hole and aftermarket fiber head gaskets I calculated compression ratio to be about 7.5 to 1. I did not want to get into the bottom end because it was solid and fresh like yours before the rain storm. I ended up having .030 milled off of my heads PLUS I believe they had already been cut once before, so I guess about .050 has been removed from the heads. My combustion chambers ended up at 75cc's. 452 heads start around 90 cc's. Now I calculate my compression ratio with the milled heads and a stock type .020 steel shim head gasket to be 10 to 1. I was able to get there without touching the bottom end. Since it looks like you are going to have to get into the bottom end any how, if you install different pistons and get them to near zero or even just .020 down you might be able to just clean up your heads and install them without milling them or maybe just a clean up cut on them and still get compression up to the 9.5 - 10 range. I think a lot depends on what you find once the bottom end is apart. If you need new pistons then get the ones you need, if you can re use your pistons you need to figure out what makes more economical sence. New pistons or head work. Most will tell you that new pistons or decking the block is the way to go, not cutting the hell out of the heads like I did. My engine guy has a few ideas, and knows just what I want. He also knows not to get too carried away with the hardware to keep the costs in line. We figure a .020 punch will clean it up, and 0 deck or close pistons will get us mostly there. Milling the heads too much leads to having to modify other things to make it fit and seal, so pistons are a better way to go if you have to get into the bottom end. Might even be able to reuse the push rods. We'll come up with a cam to make it all work together, then I can worry about what carb to run (I have three Thermoquads to choose from) what distributor, module, and all that fun stuff. I also have to go through the trans, figure out how to modify the 318 frame mounts to put the 440 in the right place, install big block torsion bars, and so on. But first things first! -AZB |

|

|

|

Post by spanks79 on Jan 1, 2014 2:05:05 GMT -5

Sounds like you got the right guy on the job. ..........Milling the heads too much leads to having to modify other things to make it fit and seal, so pistons are a better way to go if you have to get into the bottom end. Might even be able to reuse the push rods. ...... I read a lot about alignment issues from milling the heads too much. Some say the intake side of the heads or the intake itself need to be milled to match. I honestly did none of that and my intake bolted up just fine using a stock type valley pan / intake gasket. I am using an Edelbrock intake so maybe that helped, a stock I take may have given me trouble. Even with the head milling, My cam manufacturer recommended .040 to .070 of lifter preload, I was able to use stock pushrods and rockers with .020 spacers under the rocker shafts. Hopefully my combo runs well. It may be a few months until I get her fired up. Are you looking for cop 440 torsion bars or just civilian big block bars? |

|

|

|

Post by AZBlues on Jan 1, 2014 17:09:01 GMT -5

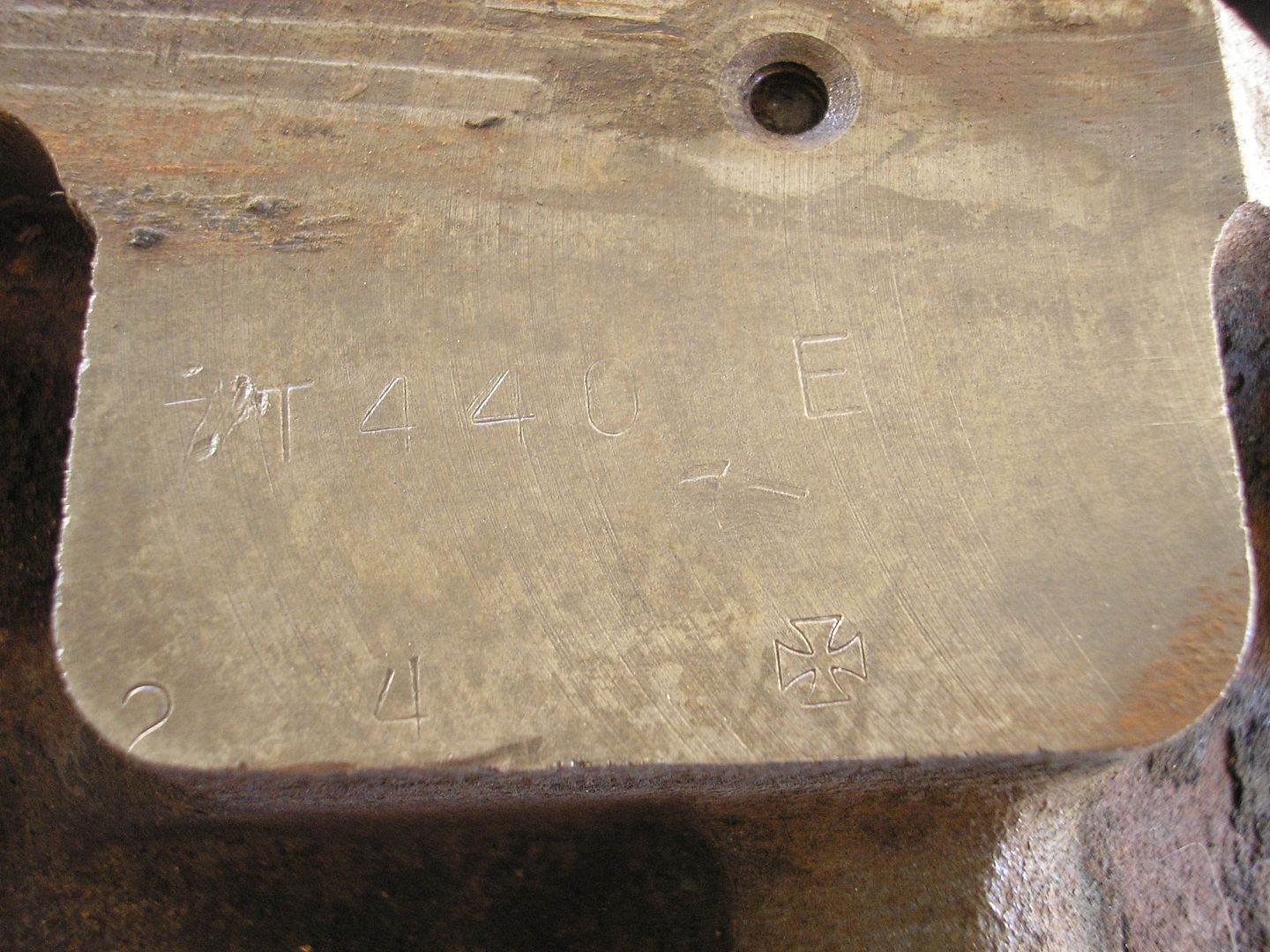

Are you looking for cop 440 torsion bars or just civilian big block bars? I'm not sure yet. I want decent handling, although everyone has a different definition of that, but I want a smooth, somewhat boaty '70s full size car ride as well; so the springs and shocks shouldn't be too stiff. Again, suggestions welcome. Some engine block numbers:   1977 440, built in the Trenton plant with a cast crank. -AZB |

|